An overview of our inline valve services

An overview of our inline valve services

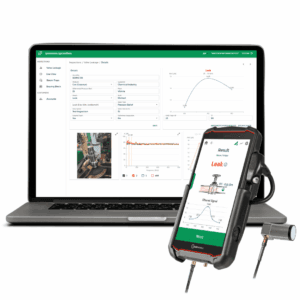

At Multimetaal, we focus on innovative solutions that enhance the safety, reliability, and efficiency of industrial installations. That is why we use Valve Sense, an advanced software-driven inspection system developed by Senseven.

Advanced leak detection based on acoustic emission

Valve Sense operates using the proven acoustic emission technique. By means of high-quality acoustic sensors and innovative smartphones (for both Ex and non-Ex zones) equipped with Senseven software, even the smallest leaks can be detected quickly and reliably.

Why Multimetaal chooses Valve Sense

Automatic detection & quantification

Valve Sense automatically detects and assesses leaks, enabling inspections to be carried out faster and with greater accuracy.

Reliable data & structured management

All measurement data is clearly stored and managed, making trend analysis, reporting, and future maintenance easier and more well-founded.

Safe deployment in all zones

Thanks to integration with explosion-safe devices from i.safe MOBILE, the system can be used safely in both hazardous and non-hazardous environments.

More insight, fewer risks

With Valve Sense, Multimetaal offers customers a smart, future-proof method for rapidly detecting valve leaks, reducing risks, and ensuring process continuity.

Additional inline services

In addition to leak rate measurements, we provide the following inline valve services for both preventive and corrective maintenance:

Pressure buildup monitoring

Cleaning*

Flushing*

Sealing*

Lubricating*

Actuator / Gearbox service

*These services are carried out using Sealweld products and equipment.

Valve fittings

For valve repair and maintenance, we use fittings from the following brands:

Sealweld

Techné

Reporting

After completion of a project, a comprehensive report is prepared detailing the work performed. This information is provided to the client and stored in the database for future reference.